The world of woodworking, metalwork, and engineering has seen important developments in recent times as a result of technological improvements. This progress not solely enhances effectivity but additionally ensures that instruments and supplies utilized by professionals in these industries meet excessive requirements for high quality and sturdiness.

One such innovation is the event of superior metalworking and woodworking machines designed with precision and accuracy in thoughts. These state-of-the-art gadgets allow craftsmen and technicians alike to create intricate designs utilizing numerous metals like metal, aluminum, brass, copper, and even treasured woods. As well as, they will produce elements or parts wanted for various purposes inside industries starting from automotive and aerospace to development and furnishings making.

Using modern-day applied sciences like computer-aided design (CAD) software program permits customers to visualise their initiatives earlier than precise implementation. With this instrument at hand, people can simply plan out each element of their venture, guaranteeing that it meets all specs whereas minimizing waste materials utilization. Moreover, CAD permits seamless collaboration between staff members engaged on complicated initiatives the place a number of disciplines come into play.

Metalwork entails processes resembling reducing, shaping, bending, welding, and ending. Every step requires specialised tools tailor-made to particular duties. As an illustration, energy hammers assist form giant items of metallic, whereas smaller handheld instruments cater to extra delicate jobs requiring finer management over actions. Equally, woodworking entails actions resembling carving, sanding, routing, drilling, and assembling. Right here too, there’s an array of devices out there catering to various ability ranges and job necessities.

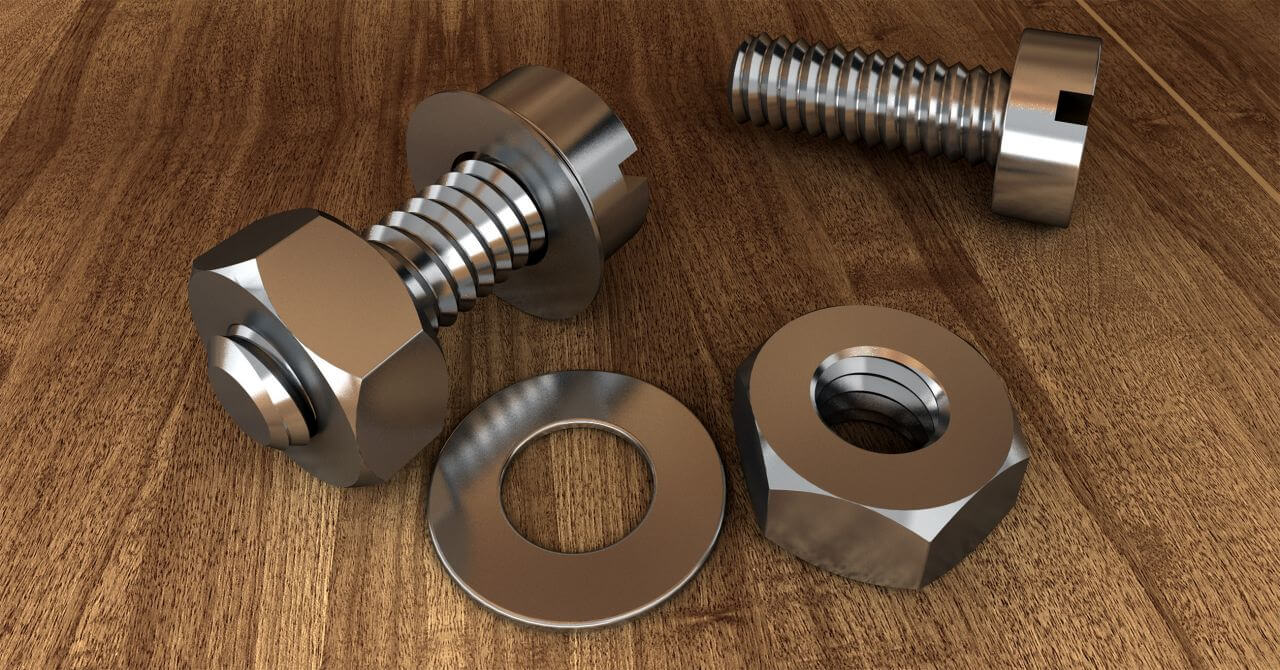

When it comes to fastening strategies, nuts, bolts, screws, washers, and different {hardware} gadgets serve important roles throughout quite a few sectors together with manufacturing, transportation, infrastructure constructing, and residential enchancment. Excessive-quality metallic components guarantee long-lasting efficiency beneath stress circumstances with out compromising security measures.

Household-owned companies usually excel in offering distinctive providers with regards to repairing broken metalworks or picket constructions. They possess beneficial expertise handed down by means of generations mixed with up-to-date information relating to present greatest practices. Such institutions often provide complete options masking every thing from minor repairs involving tightening unfastened screws or changing worn-out nuts & bolts to main restoration efforts geared toward restoring vintage furnishings again to its former glory days.

Furthermore, the rising demand for eco-friendly options led producers to discover choices using recycled supplies alongside conventional sources. Consequently, we now see elevated manufacturing strains specializing in sustainable merchandise made out of reclaimed timber or repurposed scrap metallic – contributing positively in direction of environmental conservation initiatives worldwide.

To sum up, advances in know-how proceed revolutionizing how individuals method woodworking, metalwork, and allied fields. From refined equipment able to producing exact outcomes to modern strategies selling sustainability, every facet stands testomony to the truth that regardless of being age-old crafts, these domains stay ever-evolving and adaptive to up to date wants. By embracing new developments, professionals can preserve relevance amidst quickly altering landscapes whereas delivering top-notch craftsmanship persistently.

Photo Tags

- bolt

- chrome

- Family Service

- Industry

- iron

- Metal

- nut

- repair

- ring

- screw

- Stainless

- steel

- technology

- technology metal wood work equipment wooden carpentry family service bolt repair screw visualization industry ring steel stainless thread iron chrome machinery glazed close -up nut and bolt bolts

- thread

- Visualization

- wood

- Wooden Carpentry

- Work Equipment