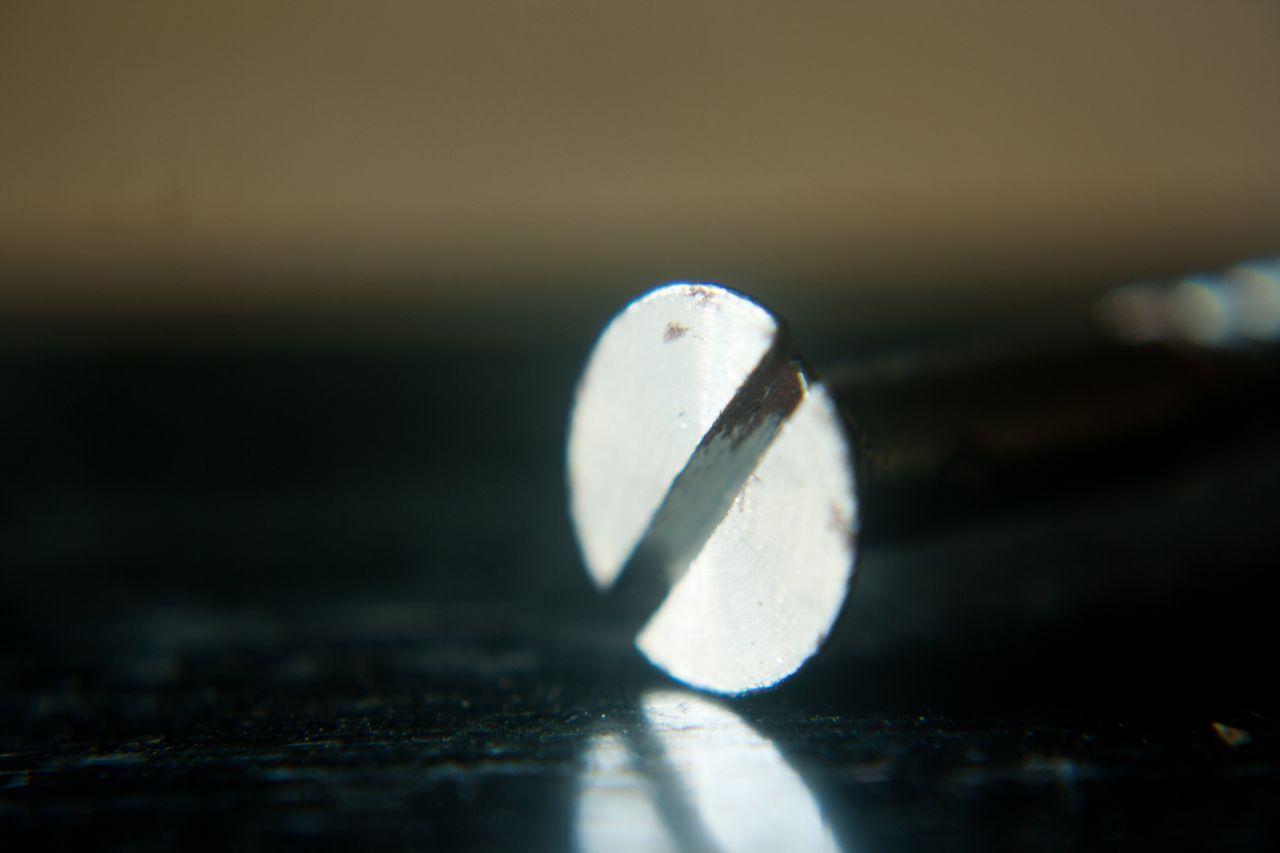

Metallic View Shut Screw Metallic Screws: A Glimpse into the World of Fasteners

In as we speak’s fast-paced world, steel screws are an indispensable part of assorted industries. These metallic fasteners are designed to carry supplies collectively, making certain stability and sturdiness. On this article, we are going to delve into the fascinating world of steel screws, exploring their varied sorts, purposes, and the manufacturing course of.

Metallic screws can be found in a variety of supplies, together with chrome steel, brass, aluminum, and varied different alloys. Every kind of steel affords distinct benefits, resembling corrosion resistance, power, and light-weight properties. The selection of fabric is determined by the particular necessities of the applying, such because the setting wherein the screw shall be used and the specified stage of sturdiness.

Probably the most frequent kinds of steel screws is the flat head screw. This sort of screw contains a flat, countersunk head that gives a flush floor when put in, making it ultimate to be used in purposes the place a low profile is crucial. Flat head screws are sometimes utilized in woodworking, electronics, and automotive industries.

One other standard kind of steel screw is the spherical head screw, which contains a rounded, dome-shaped head. This sort of screw is designed to be used in purposes the place a excessive diploma of affect resistance is required, resembling within the development business. Spherical head screws are additionally generally utilized in conditions the place the screw head must be hid.

Phillips head screws are one other extensively used kind of steel screw, that includes a cross-shaped drive that’s appropriate with a Phillips screwdriver. This sort of screw is thought for its versatility and is often utilized in a wide range of purposes, from woodworking to electronics meeting.

The manufacturing strategy of steel screws includes a number of steps, together with uncooked materials choice, materials shaping, threading, and high quality management. The method begins with the number of high-quality uncooked supplies, that are then heated and shaped into wire. The wire is then minimize to the specified size and formed right into a screw, with the top and threads being shaped utilizing specialised equipment.

As soon as the steel screws have been shaped, they endure a threading course of to create the screw’s helical groove, which permits it to interact with the corresponding nut or threaded gap. The threading course of may be achieved via varied strategies, resembling rolling, reducing, or grinding.

Lastly, steel screws endure a rigorous high quality management course of to make sure that they meet the mandatory requirements for power, sturdiness, and efficiency. This course of might contain visible inspection, dimensional measurement, and testing for corrosion resistance and tensile power.

In conclusion, steel screws are an integral part of recent society, serving as an important hyperlink between varied supplies and constructions. Their versatility, sturdiness, and flexibility make them a significant software in a variety of industries. As we proceed to innovate and develop new supplies and applied sciences, it’s sure that the world of steel screws will proceed to evolve and adapt to fulfill the calls for of an ever-changing world.